The modern industrial fanis undergoing a significant transformation, evolving far beyond its traditional role of simply moving air. Today's market reflects a clear trend towards highly engineered solutions that blend sophisticated design, energy efficiency, and application-specific functionality. For businesses ranging from large-scale manufacturing plants to specialized workshops, understanding these trends is crucial for optimizing operations, ensuring workplace safety, and reducing long-term costs. The focus has shifted from brute force airflow to intelligent, sustainable, and integrated air management systems.

The Evolution of Design and Materials

One of the most visible trends inthe industrial fansector is the emphasis on advanced design and materials. Gone are the days of purely utilitarian, uninspired equipment. Modern fans now often feature vibrant, powder-coated finishes, which not only provide a sleek, contemporary aesthetic but also offer superior corrosion resistance and durability in harsh industrial environments. This trend is exemplified by designs featuring vivid orange or blue cylindrical housings. Furthermore, blade technology has advanced significantly. Aerodynamically engineered multi-blade setups are becoming the standard, designed to maximize airflow efficiency while minimizing noise and drag. This fusion of form and function ensures that today's fans are not only built to last but also to perform at an optimal level.

Efficiency and Sustainability at the Core

The global push towards sustainability has heavily influenced the development ofindustrial ventilation fans. The latest models are engineered with low power consumption as a primary goal, allowing facilities to reduce their carbon footprint and operational expenses without sacrificing performance. This is particularly vital for systems that run continuously. The integration of these fans into larger systems, such as inHVAC industrial fansapplications, demands this high level of efficiency to maintain cost-effective climate control in vast spaces. By combining powerful motors with lightweight, high-performance propellers, manufacturers are delivering robust solutions that meet both economic and environmental standards.

Versatility and Application-Specific Solutions

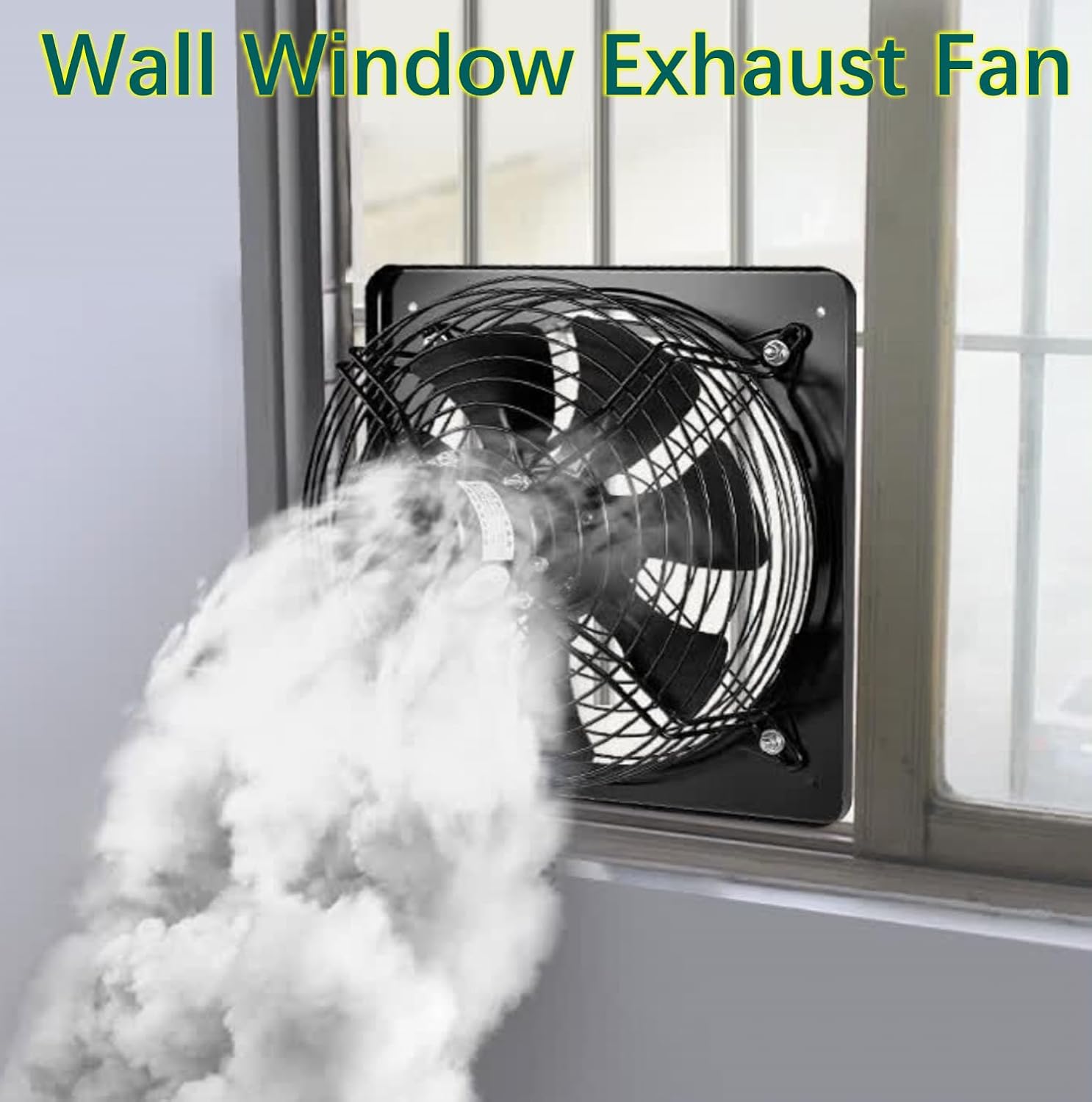

The modern industrial landscape is diverse, and the one-size-fits-all approach to ventilation is no longer viable. A key trend is the development of specialized fans tailored to specific tasks. For instance, a high-velocity axial-flow fan might be perfect for general circulation in a warehouse, while a dedicatedindustrial exhaust fanwith a heavy-duty frame is required for venting heat, smoke, or fumes from a manufacturing process. The market also includes a wide array of options like powerfulindustrial ceiling fansdesigned for destratification in high-ceilinged buildings. Features like compact structures and versatile mounting brackets further enhance this adaptability, allowing for easy installation on walls, ceilings, or within ductwork to meet the unique layout of any facility.

Integrated Safety and Sourcing

Alongside performance, safety remains a non-negotiable priority. Modern fans feature robust protective grilles that prevent accidental contact with moving blades without obstructing airflow. This focus on safety is part of a larger trend towards integrated solutions where businesses seek reliable, comprehensive systems. Companies like Ningbo Aoshun Electrical Co., Ltd. cater to this need by offering a one-stop purchasing experience for all electrical and ventilation requirements. This approach not only simplifies procurement for wholesalers and buyers but also ensures that every component, from the main fan to ventilation accessories, is compatible and meets consistent quality standards, reflecting a forward-thinking approach to modern industrial needs.