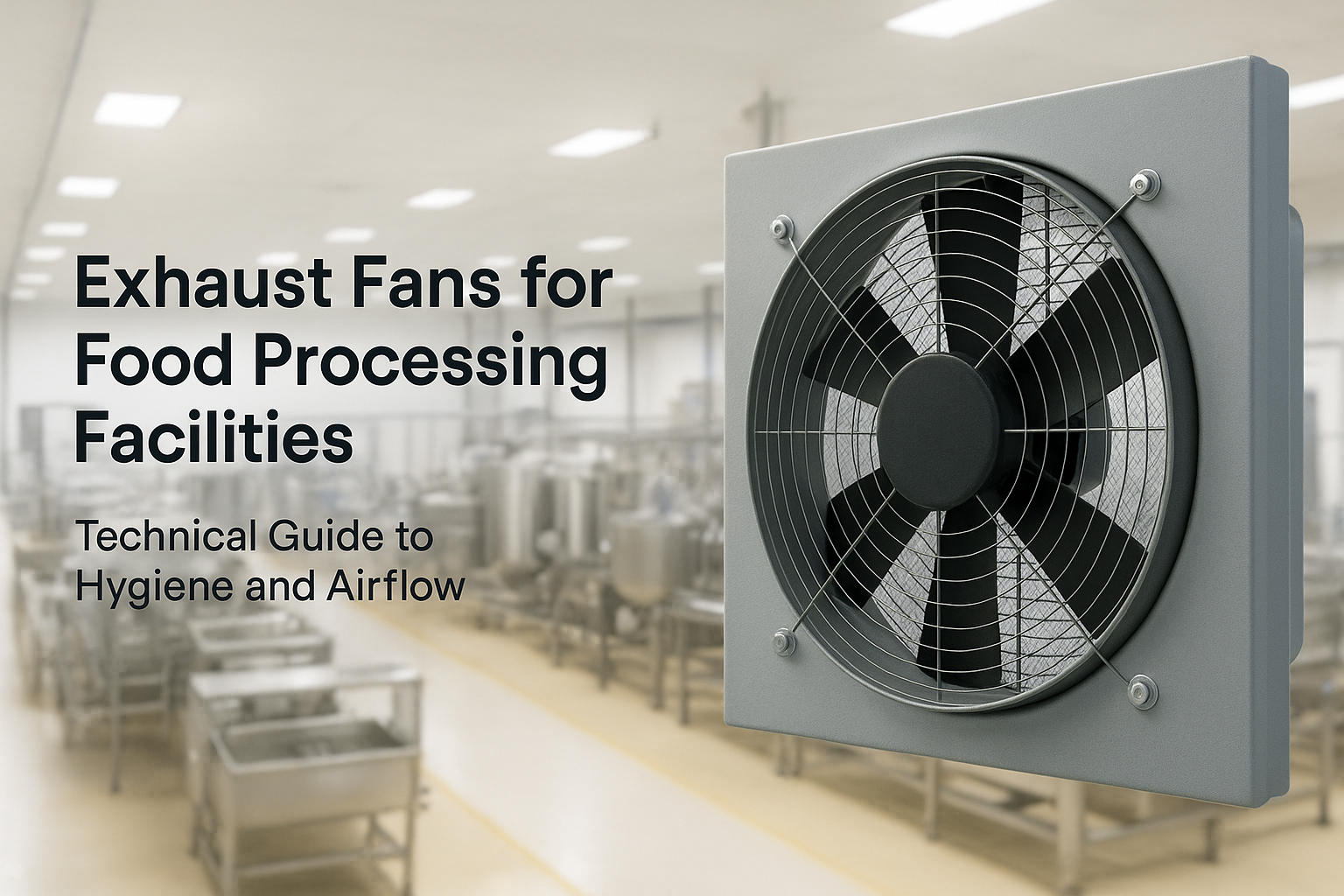

Exhaust Fans for Food Processing Facilities: Technical Guide to Hygiene and Airflow

In food processing, air quality is a critical control point. Steam, odors, fine particulates, and airborne oils from cooking or preparation can settle on surfaces, contaminate products, and compromise hygiene. A correctly engineered exhaust fan for food processing does more than extract air—it actively manages airflow patterns, humidity levels, and contamination risks while meeting HACCP and food safety compliance requirements.

Controlling Airborne Contaminants

Processing lines generate fine particles from flour, spices, or powdered ingredients, which can remain suspended and spread across production areas. Without targeted exhaust, these particulates settle on packaging and equipment, creating a hygiene risk and requiring frequent cleaning.

Solution: Install directional exhaust fans with ducting that draws contaminants directly away from processing lines and towards filtration or safe discharge points. Fans should have washdown-rated housings (IP55–IP66) to allow for regular cleaning without damage.

Managing Moisture and Steam

Cooking, washing, and sanitation processes release large amounts of steam into the air. Excess humidity condenses on cold surfaces, encouraging bacterial growth and corrosion of metal equipment.

Solution: Use humidity-controlled exhaust fans to maintain relative humidity (RH) below 60%. Ceiling or wall-mounted units in stainless steel are corrosion-resistant and withstand repeated washdowns. Integrating intake fans helps replace exhausted air with filtered, dehumidified supply.

Temperature and Air Pressure Balance

Temperature-sensitive products such as dairy or baked goods require stable climate control. Poorly balanced exhaust can create negative pressure, drawing in unfiltered air through open doors or cracks.

Solution: Design ventilation systems with matched intake and exhaust volumes. Use variable speed exhaust fans to adjust airflow during peak or low production periods, maintaining temperature and preventing uncontrolled infiltration.

Compliance and Material Requirements

Food processing exhaust systems must comply with hygiene and safety standards:

-

Material: Stainless steel or food-grade coated metals.

-

Design: Smooth, crevice-free surfaces to avoid bacterial harborage.

-

Washdown Capability: Rated for high-pressure, high-temperature cleaning.

-

Standards: HACCP-aligned design; some facilities may require USDA or EHEDG-compliant equipment.

Technical Performance Factors

-

Airflow Capacity (CFM/ACH): Based on room volume and contaminant load.

-

Motor Type: Sealed motors for moisture resistance; ECM for energy savings.

-

Filtration: Pre-filters or HEPA for re-circulating systems.

-

Noise: Maintain <65 dB in work areas to meet occupational comfort guidelines.

-

Placement: Near steam sources, above high-particulate equipment, and in sanitation zones.

Quick Reference Table

| Challenge | Risk | Recommended Indicators | Fan Solution |

|---|---|---|---|

| Airborne particulates | Cross-contamination | Targeted exhaust, washable housing | Washdown-rated directional fan |

| Moisture & condensation | Bacterial growth, corrosion | RH < 60%, humidity sensors | Stainless steel humidity-controlled fan |

| Temperature stability | Product quality loss | Balanced intake/exhaust, variable speed | ECM variable-speed exhaust fan |

| Hygiene compliance | Regulatory violation | Food-grade materials, smooth finish | HACCP-compliant stainless exhaust fan |

Why Aosair’s Fans Excel in Food Processing Environments

-

Hygienic Design: Stainless steel housings with crevice-free construction.

-

Durability: IP-rated motors and components for washdown resistance.

-

Performance: High CFM with balanced intake/exhaust engineering.

-

Custom Options: OEM and tailored solutions for specific processing lines.

Maintaining a clean, safe, and compliant food production environment starts with a ventilation strategy built for your process. Explore our food processing exhaust fan solutions or contact our engineers via the contact page for a tailored airflow and hygiene compliance plan.