Creating a safe, comfortable, and productive work environment hinges on effective air quality management. Whether in a sprawling factory, a bustling workshop, or a commercial renovation site, the right equipment is essential for circulating fresh air and removing harmful contaminants. A high-qualityindustrial extractor fanis a cornerstone of this system, designed to handle the rigorous demands of professional settings by ensuring consistent airflow and ventilation where it's needed most.

Understanding the Different Types ofIndustrial Fans

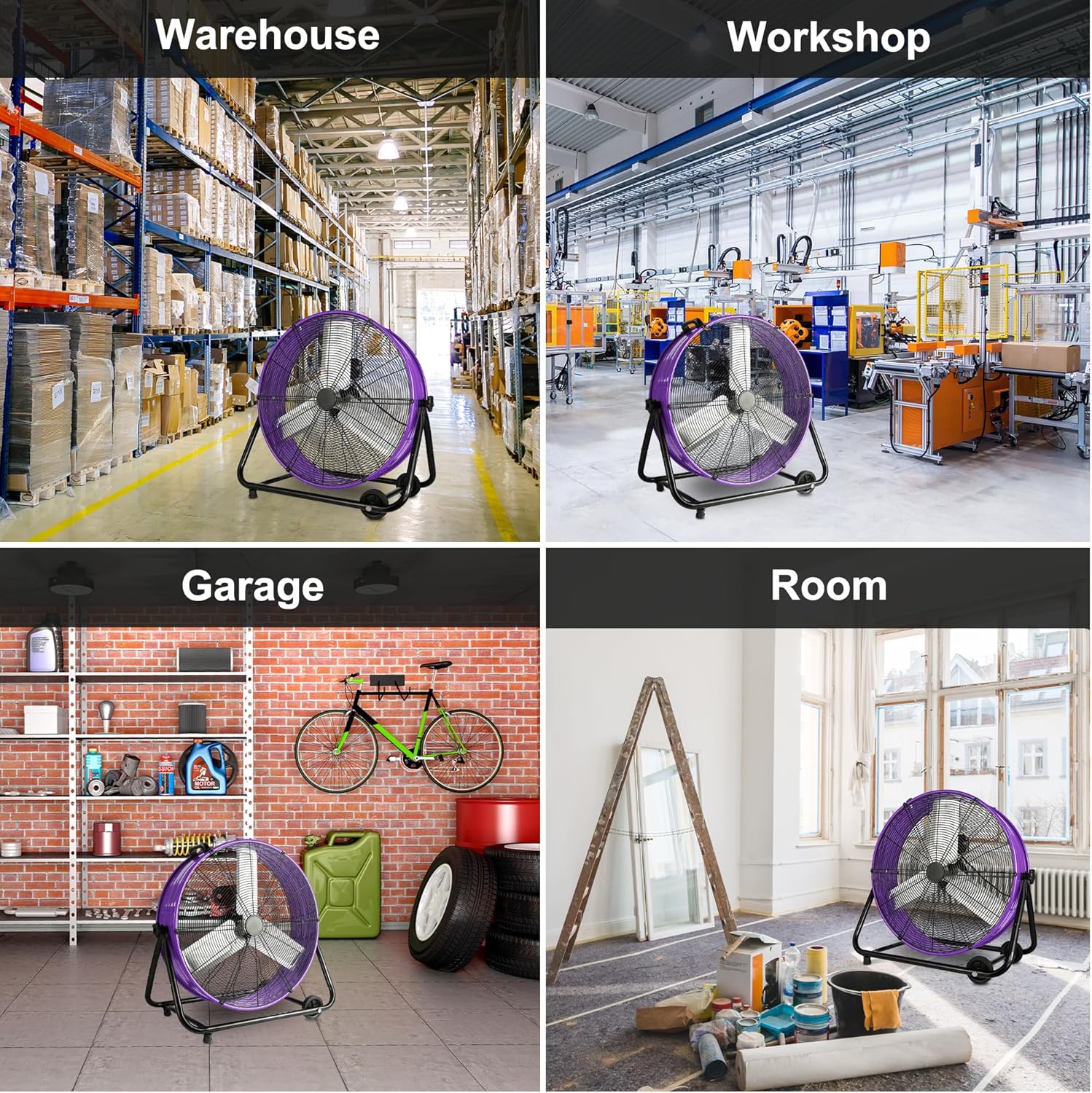

When selecting anindustrial ventilationsolution, it is important to understand the different types available to meet specific needs. For general-purpose air circulation and drying, portable floor fans mounted on sturdy tripods offer incredible versatility. These units can be easily moved and positioned to direct powerful airflow exactly where required, accelerating paint drying or clearing fumes. For more specialized tasks like water damage restoration, compact and efficient models are designed to maximize moisture removal. Beyond portable options, permanentlyinstalled industrial exhaust fansare critical for systematically removing stale, contaminated air from a building and replacing it with fresh outdoor air. In large spaces like warehouses or assembly halls,an industrial ceiling exhaust fanprovides an ideal solution, offering broad, consistent air exchange without occupying valuable floor space.

Key Features of aHigh Performance Extractor Fan

Not all fans are created equal, and choosing ahigh performance extractor faninvolves looking at several key features. Durability is paramount; look for fans with robust, sturdy construction and reinforced designs that can withstand the rigors of an industrial environment. The motor and blade design directly impact performance, so powerful airflow is a must for effective ventilation. Versatility is another critical factor. Features like adjustable ropes, secure D-ring attachments for stable positioning, and variable speed controls allow you to tailor the fan's operation to the specific demands of any project. A lightweight, portable design also adds significant value, making it easy to transport the fan between job sites or different areas of a facility.

Practical Applications forIndustrial Cooling Fans

The applications for industrial fans are vast and varied. In manufacturing and workshop environments, an industrial air extractor is indispensable for removing welding fumes, sawdust, and other airborne particles, protecting worker health. They also play a crucial role in temperature control, as industrial cooling fans can significantly lower ambient temperatures in hot environments like foundries or commercial kitchens, reducing heat stress and improving productivity. In construction and renovation, these fans are used to ventilate enclosed spaces, cure concrete, and dry paint and plaster. Their powerful air-moving capabilities make them a vital tool for ensuring projects stay on schedule while maintaining a safe atmosphere.

Choosing a Reliable Ventilation Partner

Finding the right fan is only half the battle; you also need a supplier you can trust. Partnering with a company that offers a comprehensive range of products, from portable units to a complete industrial ceiling exhaust fan system, simplifies the procurement process. A one-stop purchasing experience ensures you can find the perfect solution for all your electrical and ventilation needs. Look for a supplier with a proven track record in flexible design and production, as well as robust global logistics that can deliver your equipment anywhere in the world. A reliable partner will work with you to ensure you get not just a product, but a complete ventilation solution that enhances the safety and efficiency of your operations.