Regular maintenance is key to keeping yourventilation fansrunning smoothly and efficiently.

Whether used in residential, commercial, or industrial settings, proper upkeep helps:

✅ Extend product life

✅ Maintain airflow performance

✅ Reduce noise

✅ Prevent costly repairs

In this guide,AOSAIRshares practicalventilation fan maintenance tipsto help users and facility managers optimize fan performance.

Why Maintain Ventilation Fans?

Benefits of regular maintenance:

✅ Ensures consistent air quality

✅ Prevents motor overheating

✅ Maintains energy efficiency

✅ Complies with health and safety standards

✅ Reduces downtime in commercial/industrial environments

1️⃣ General Maintenance Tips for All Ventilation Fans

✔️ 1. Regular Cleaning

-

Dust and debrisbuildup on blades and motor can reduce efficiency

-

Clean fan blades and housing with a soft cloth or brush

-

For heavy buildup, use a mild detergent (check manufacturer guidance)

✔️ 2. Inspect Electrical Connections

-

Ensure wires and terminals are secure

-

Look for signs of wear, corrosion, or damage

-

Have a qualified electrician service connections if needed

✔️ 3. Check Fan Balance

-

Unbalanced blades can causenoise and vibration

-

Ensure blades are clean and free from deformation

✔️ 4. Lubricate Bearings (if applicable)

-

Some industrial fans havelubrication points

-

Follow manufacturer schedule for adding lubricant

-

Do not over-lubricate — can cause motor strain

2️⃣ Specific Maintenance by Fan Type

✔️ Wall-Mounted Ventilation Fans

-

Check mounting hardware for tightness

-

Ensure grille and louvers are clean and move freely

✔️ Ceiling-Mounted Fans

-

Checkceiling mount integrity— no sagging or loose components

-

Verify duct connections are sealed properly

✔️ Inline Duct Fans

-

Inspect ductwork forobstructions

-

Ensure flexible ducts are not kinked or collapsed

-

Clean fan housing and blades periodically

✔️ Industrial Exhaust Fans

-

Followscheduled maintenance intervalsfor high-use environments

-

Check for grease buildup (especially in kitchen applications)

-

Inspect motor and drive components (belts, pulleys if used)

3️⃣ Common Signs Maintenance Is Needed

❌ Unusual noise or vibration

❌ Reduced airflow

❌ Excessive motor heat

❌ Visible dust/grease buildup

❌ Higher energy consumption than normal

4️⃣ Maintenance Frequency Recommendations

| Environment | Suggested Maintenance Frequency |

|---|---|

| Residential | Every 6–12 months |

| Commercial | Every 3–6 months |

| Industrial | Monthly to quarterly, depending on use |

5️⃣ When to Replace Your Ventilation Fan

Even with good maintenance, fans eventually wear out. Consider replacement if:

✅ Fan is 8–10+ years old

✅ Motor noise increases significantly

✅ Fan fails to maintain airflow despite cleaning

✅ Repairs become frequent and costly

6️⃣ How AOSAIR Supports Long-Term Performance

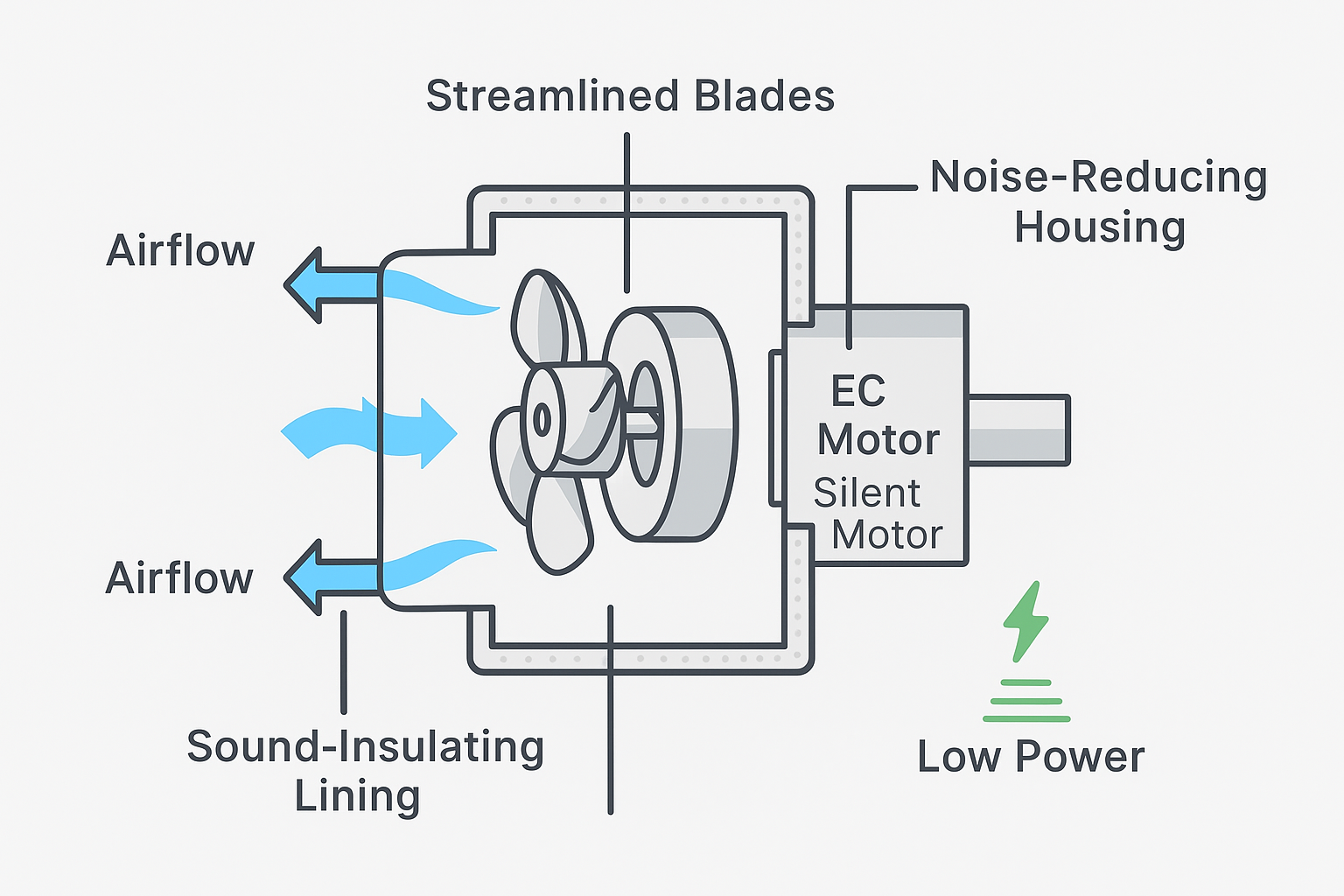

AOSAIRdesignsOEM ventilation fanswith:

✅ Easy-clean features

✅ Low-maintenance motors

✅ Durable construction for extended service life

✅ Replacement parts and support for project clients

7️⃣ Need Help Choosing New or Replacement Fans?

If you're planning toupgrade your ventilation systemor sourceOEM ventilation fans:

👉 Visit ourProducts pageorcontact us here.

We’ll help you select:

✅ Energy-efficient models

✅ Low-maintenance designs

✅ Quiet operation options

✅ Custom OEM solutions for your market

Conclusion

Regular maintenance is the key toefficient and long-lasting ventilation fans.

Follow these tips to optimize performance — and when it's time for new fans,AOSAIRis here to support your needs!